Our Story

Driving sustainable agriculture

Driving sustainable agriculture

Since our establishment in 2005, research and development have been the cornerstone of our work.

After extensive studies on the crop nutrition market, we made the strategic decision to invest in potassium production—an essential nutrient for agriculture.

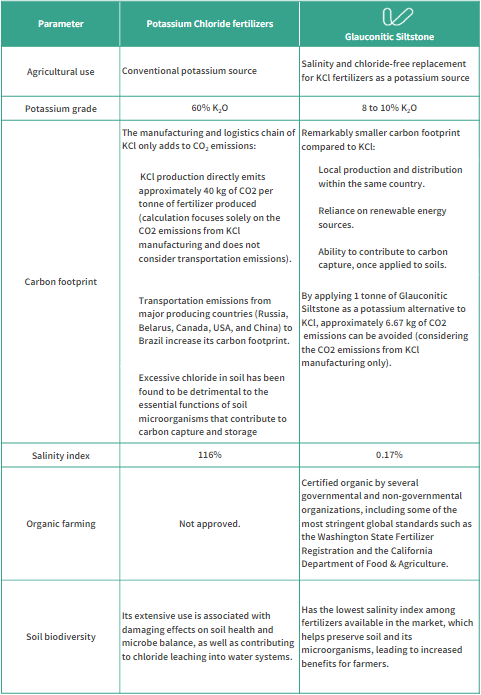

Traditionally, Potassium Chloride, also known as KCl, has been the primary fertilizer used as a potassium source. However, studies have uncovered the adverse effects of excessive chloride on soil health and microbiome balance.

In contrast, our focus has been on conducting research in Brazil to identify sustainable agricultural initiatives that not only enhance soil biodiversity but also promote long-term ecological balance.

Recognizing the potential of integrating agriculture and carbon capture solutions, we set out to make a positive global impact.

Assessing our resources

Assessing our resources

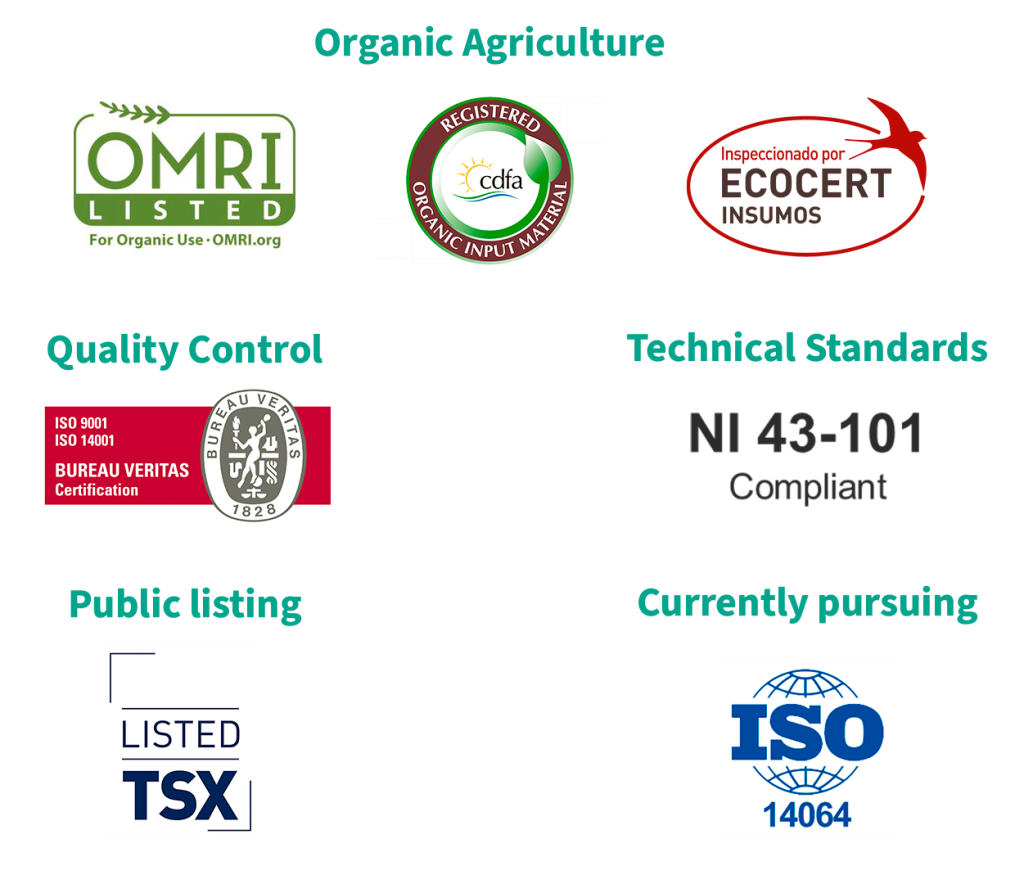

Following extensive geological research, including over 40,000 meters of drilling and chemical analysis, we commissioned an independent mineral resource and reserve study compliant with the Canadian National Instrument 43-101 standard.

This study revealed mineral resources exceeding 3.32 billion tonnes of naturally occurring Glauconitic Siltstone, also known for its potassium content, a vital nutrient for plant growth.

This geological occurrence is situated in the state of Minas Gerais, Brazil, near key food-producing regions.

Our resource's strategic location plays a vital role in reducing carbon emissions linked to the transportation and distribution of minerals. This fosters a more sustainable supply chain, aligning with our commitment to environmental responsibility.

Developing our products

Developing our products

The introduction of our flagship product, K Forte® (also known as Super Greensand®), played a pivotal role in our journey.

Developed through our proprietary technologies, K Forte® has demonstrated its ability to enhance soil fertility, improve water retention, and nourish crops, resulting in healthier plants and significantly increased yields.

In 2020, we expanded our product line with the launch of BAKS®, an innovative solution that combines K Forte® with carefully selected nutrients. This breakthrough allows farmers to customize nutrient compositions based on the unique requirements of each crop.

BAKS® provides a cost-efficient option by consolidating multiple nutrients into a single fertilizer, reducing the frequency of applications throughout the year and resulting in operational cost savings for farmers.

From 2017 to 2022, we successfully deployed 1.4 million tonnes of our products in agricultural soils, showcasing the widespread adoption and trust placed in our solutions by farmers worldwide.

Biologicals in agriculture: The game-changer

Biologicals in agriculture: The game-changer

In 2022, we launched Bio Revolution, our technology that allows the incorporation of microorganisms into mineral fertilizers.

Setting a new standard in the industry, K Forte® became the world's first fertilizer to utilize the Bio Revolution technology.

Bacillus aryabhattai, globally renowned for its significant agricultural benefits, was the first microorganism incorporated into our products.

Biologicals are a game-changing approach to the field of agriculture, delivering a multitude of significant benefits throughout its value chain.

The adoption of biologicals brings about a transformative shift, offering improved soil health, reduced input costs, higher crop yields, diminished greenhouse gas emissions, enhanced customer satisfaction, and increased income for farmers.

Today, we hold the distinction of being the largest company in the world that produces mineral fertilizers with added microorganisms.

Starting our operations and growing our business

Starting our operations and growing our business

In 2018, Verde built its first production facility, Plant 1, and began commercial production.

Within a few years, we undertook expansion efforts to increase the production capacity of Plant 1 to 0.6 million tonnes per year (Mtpy).

In 2020 and 2021, we experienced sold-out production.

In 2022, we initiated and successfully completed the construction of our second production facility, Plant 2. The expansion process for Plant 2 was finalized within the same year, doubling its production capacity from 1.2 Mtpy to 2.4 Mtpy.

Furthermore, we operate a Bioproduction facility, designed for large-scale production of biological additives and the incorporation of microorganisms into our products using our proprietary technology, Bio Revolution.

In addition to our production plants, we also operate three research laboratories focusing on Microbiology, Mineralogy, and Agronomy. To date, our investments in R&D and infrastructure have surpassed C$111 million.

Where we stand

Where we stand

Today we have the potential to develop one of the world's largest carbon capture projects.

Through Enhanced Rock Weathering, each tonne of our product has the potential to permanently capture 120 kg of CO2 from the atmosphere, while simultaneously providing potash to plants, an essential nutrient.

As Brazil's largest potash producer by capacity, our installed overall production capacity is 3,000,000 tpy, translating to a CDR potential of 360,000 tons per year, with no requirement for additional CAPEX.

Looking ahead

Looking ahead

Our goal is to achieve an annual production capacity of 50 million tonnes, establishing Verde AgriTech as one of the world's largest carbon capture projects.

By accomplishing this milestone, we aim to permanently remove up to 6.0 million tonnes of CO2 from the atmosphere annually.

Furthermore, we are committed to remaining at the industry forefront by developing innovative technologies and pioneering new products.

Through continuous investments in research and development, as well as operations optimization, we bring together the best of nature and technology to revolutionize agriculture, making it healthier, more productive, profitable, and sustainable.